Current Research Projects

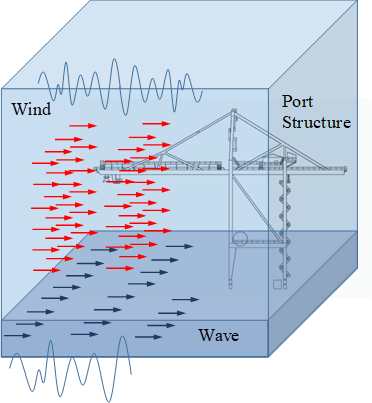

Port Infrastructure Resilience through Combined Wind-Surge Demand Characterization

with Kaley Collins

Funded by the Maritime Transportation Research and Education Center

United States coastal ports facilitate the import and export of essential commodities (crude oil, food, electronics, plastics, etc.) and are a key infrastructure allowing our national economy to function. Due to their proximity to costal waterways, many US ports are susceptible to the deleterious effects of storm water surge which are often accompanied by extreme winds and can lead to infrastructure damage and service interruptions (with severe economic consequences). Accurately estimating and understanding storm surge demands is crucial for accurate evaluation and resilient design of port infrastructure. This project aims to understand the interactive effects of severe wind and storm surge demands on port infrastructure and to develop hazard demand models to aid improvements to infrastructure design resilience.

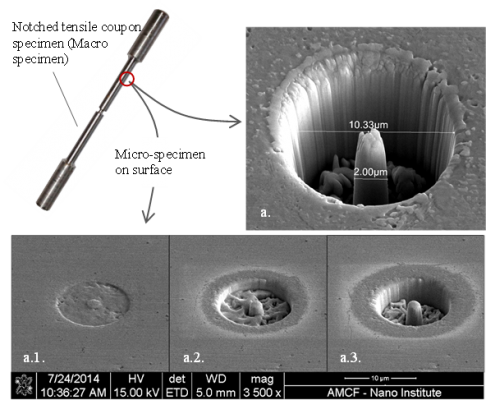

CAREER: A Micro-Mechanics Based Approach to Ductile Fracture Simulation in Additively Manufactured

Steels for Seismic Structural Fuse Design:

with David Gonzalez Nino

Funded by the U.S. National Science Foundation (NSF)

Award Number: 1751699

Emerging AM technologies (such as 3-D metal printing) are promising for performance-based optimization of steel systems, as they can accommodate highly irregular component designs through highly controlled weld-free geometry formation. However, in order for AM steel parts to transition to functioning components in structural steel systems, the ability to predict damage limit states, such as ductile fracture and low-cycle fatigue, is needed. Existing ductile fracture models lack the ability to accurately capture fracture processes in AM steel alloys due to the complex micro features formed during fabrication. This research aims to characterize the fundamental processes driving ductile fracture in AM steel alloys through nano-mechanical testing and develop models for predicting macro-scale fracture behavior in seismic structural fuse components.

^ – Preliminary (proof-of-concept) nano-scale tension test on an S355 steel sample using a Bruker PI88 pico-indenter in reverse operation. Specimen width is approximately 1 micron.

![]() Gonzalez-Nino, D., Sonntag, S., Afshar-Mohajer, M., Goss, J., Zou, M., and Prinz, G.S. (2021). “Micromechanical tension testing of additively manufactured 17-4PH stainless steel specimens.” J. Vis. Exp., (170)e62433.

Gonzalez-Nino, D., Sonntag, S., Afshar-Mohajer, M., Goss, J., Zou, M., and Prinz, G.S. (2021). “Micromechanical tension testing of additively manufactured 17-4PH stainless steel specimens.” J. Vis. Exp., (170)e62433.

![]() Gonzalez-Nino, D., Strasser, T., and Prinz, G.S. (2021). “Ultra low-cycle fatigue behavior comparison between additively manufactured and rolled 17-4PH (AISI 630) stainless steels.” Metals, 11(11), 1726.

Gonzalez-Nino, D., Strasser, T., and Prinz, G.S. (2021). “Ultra low-cycle fatigue behavior comparison between additively manufactured and rolled 17-4PH (AISI 630) stainless steels.” Metals, 11(11), 1726.

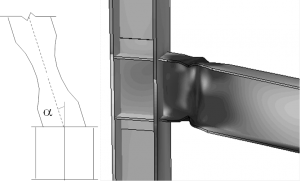

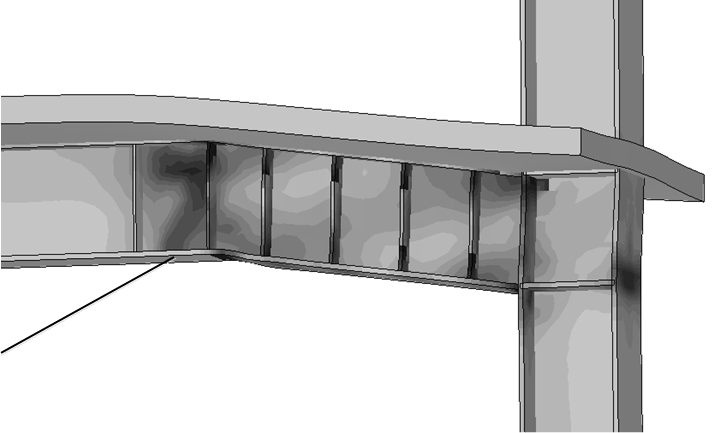

Steel Seismic Systems with Architectural Flexibility: Seismic Performance of Non-Orthogonal

SMF Beam-to-Column Connections

with Damaso Dominguez, Hossein Kashefizadeh, and Sarah Alimirzaie

Funded by the American Institute of Steel Construction (AISC)

Architectural constraints often arise in the design of steel buildings, challenging structural design approaches and sometimes limiting the competitiveness of steel as a construction material. As building functions continue to evolve, future design approaches must be flexible enough to accommodate architectural forms that deviate from traditional rectangular framing. Seismic systems and connection designs that improve the architectural flexibility of steel structures are needed. When moment frames are made to conform to some architectural features, skew may occur at the beam-column connections. Current SMF connection design procedures do not consider skew and it is unclear how much skew should be permitted in design. This project focuses on developing comprehensive seismic design guidelines for skewed RBS moment connections through both full-scale experimental testing and detailed parametric finite element analyses.

![]() Dominguez, D., and Prinz, G.S. (2021). “Cyclic behaviour of laterally skewed special moment frame connections having composite concrete slabs.” Steel Construction, 14(2021).

Dominguez, D., and Prinz, G.S. (2021). “Cyclic behaviour of laterally skewed special moment frame connections having composite concrete slabs.” Steel Construction, 14(2021).

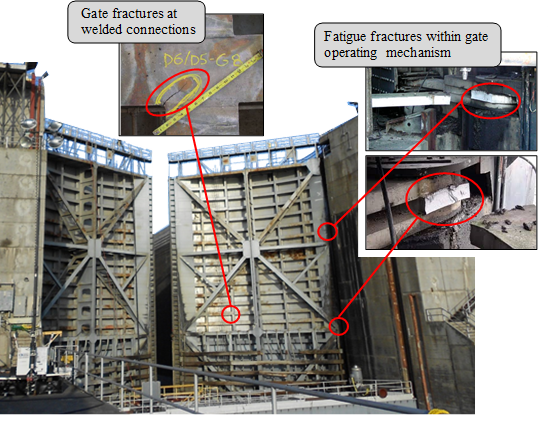

Fatigue Crack Control in Waterway Lock Gate Pintle Locations Subjected to Multi-Modal Fracture

with Logan Verkamp

Funded by the Maritime Transportation Research and Education Center (MarTREC)

This research project addresses multi-mode fatigue cracking within critical lock gate pintle locations. The lock gate pintle is a ball-and-socket joint that is crucial for proper gate operation, but is subject to frequent fatigue cracking. Fatigue crack repair within pintle locations is particularly challenging due to the complex multi-axial loading conditions (combined axial and torsional loads) that occur during gate opening and closing. The project currently underway uses both analytical investigations and component experiments to assess multi-axial stress demands within common pintle geometries during operation, and develop bonded fiber reinforced polymer (FRP) retrofits capable of controlling multi-mode fractures (fractures that originate from both tensile and shear stresses).

![]() Lozano, C., Langston, M., Kashefizadeh, M-H., and Prinz, G.S. (2022). “Analytical and experimental investigation into pre-stressed carbon fiber reinforced polymer (CFRP) fatigue retrofits for steel waterway lock-gate structures.” Metals, 12(1), 88.

Lozano, C., Langston, M., Kashefizadeh, M-H., and Prinz, G.S. (2022). “Analytical and experimental investigation into pre-stressed carbon fiber reinforced polymer (CFRP) fatigue retrofits for steel waterway lock-gate structures.” Metals, 12(1), 88.

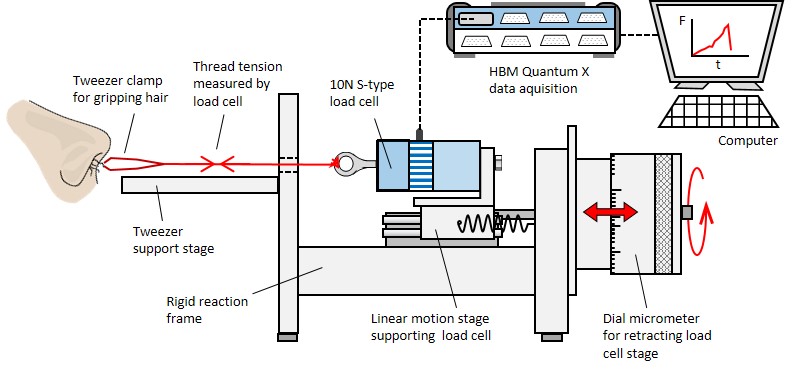

On the Pullout Strength of Human Nasal Hair

with Cameron Murray

Funded by human curiosity

The bristly hairs within the human nasal cavity operate to filter environmental contaminants, humidify inhaled air, and are similar in structure to external whiskers common on many mammals. As foreign contaminants accumulate and solidify within the nasal cavity, contaminant removal may result in pullout of the nasal hair (removal of the root from the nasal dermis) which can be painful. Additionally, medical nasal packings (common following nasal surgeries) or instruments that are required to enter the nasal cavity for contaminant removal may sometimes adhere to the nasal hairs resulting in undesirable hair pullout, subsequent pain, and even folliculitis (a skin condition resulting in inflamed hair follicles). Improved understanding of nasal hair pullout in humans could help future nasal packing design and contaminant removal procedures where nasal hair pullout should be avoided, or even aid certain cosmetic procedures where nasal hair removal via pullout is the objective. In this study, pullout behavior of human nasal hair is investigated using sensitive force-measuring equipment and advanced scanning electron microscopy.

![]() Prinz, G.S., and Murray, C.D. (2021). “On the pullout strength of human nasal hair.” Materialia,

Prinz, G.S., and Murray, C.D. (2021). “On the pullout strength of human nasal hair.” Materialia,

[Accepted].

Towards a Fast Reconstruction Paradigm for Urban Environments in Developing Regions

Affected by Natural Disasters:

with Chris Maestri and Julian Fairey

Funded by the UofA Engineering Research & Innovation Seed Fund

Disasters in developing regions often destroy homes and contribute to unstable economic conditions that force people to live in temporary shelters for extended periods of time. This ERISF research project aims to gather preliminary data to support a novel fast rebuilding paradigm for urban environments in developing regions affected by natural disasters. The focus of the project is on multi-story, multi-purpose element, urban shelter concepts, having fully integrated simple water collection (SWAC) systems. A multi-purpose structural element is one that is locally produced in the affected area for an application not related to the shelter construction, but whose mechanical properties are well suited for carrying structural loads. In general, the multi-purpose shelter elements must be low-cost, lightweight, quickly and easily fabricated at an industrial scale, durable, and have good structural properties to allow construction of multiple stories. Example multi-purpose elements include: light-gauge steel tubing from ventilation ducts, signposts, discarded drill-piping, roadway guardrails, drain gutters, etc.

Prinz, G.S., and Nussbaumer, A. (2013). “On fast transition between shelters and housing after natural disasters in developing regions,” Chapter in “Technologies for Sustainable Development: A Way to Reduce Poverty?”, Springer-Verlag.

Prinz, G.S., and Nussbaumer, A. (2013). “On fast transition between shelters and housing after natural disasters in developing regions,” Chapter in “Technologies for Sustainable Development: A Way to Reduce Poverty?”, Springer-Verlag.

Concluded Research Projects

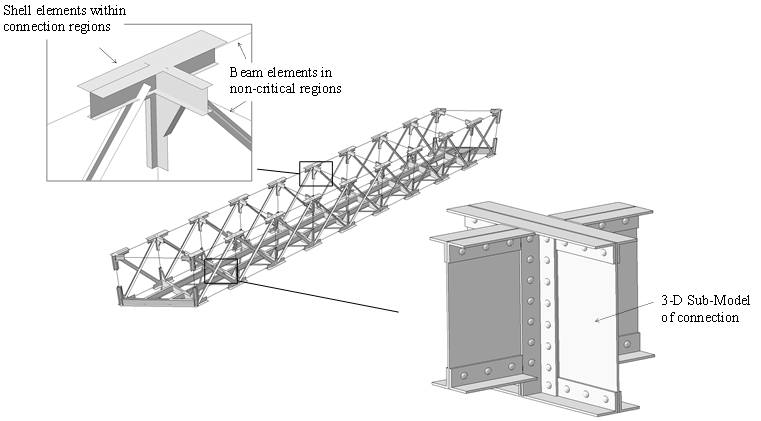

Fatigue of Welded Shear Connectors in Composite Steel Bridge Beams:

with Brianna Ovuoba and Brian Hillhouse

Funded by W&W|AFCO Steel and the American Institute of Steel Construction (AISC)

Fatigue often governs in the design of composite steel bridge girders, and a large number of shear connectors are often required. With the current AASHTO fatigue requirements assuming a lower shear-connector fatigue capacity than comparable specifications throughout the world, the current research project re-evaluates existing fatigue test data using a more quantifiable probabilistic approach. In addition, double-sided push-out fatigue tests are conducted to add to the existing S-N curve data sets. (Photo credit: Grady Harvell, W&W | AFCO Steel)

![]() Hillhouse, B., and Prinz, G.S. (2019). “Effects of clustering and flange surface friction on headed shear stud demands.” Journal of Constructional Steel Research, [Under Review].

Hillhouse, B., and Prinz, G.S. (2019). “Effects of clustering and flange surface friction on headed shear stud demands.” Journal of Constructional Steel Research, [Under Review].

![]() Ovuoba, B., and Prinz, G.S. (2018). “Analysis of shear stud fatigue demands in composite bridge girders having varied stud pitch, girder depth, and span length.” Journal of Bridge Engineering, ASCE, 23(11).

Ovuoba, B., and Prinz, G.S. (2018). “Analysis of shear stud fatigue demands in composite bridge girders having varied stud pitch, girder depth, and span length.” Journal of Bridge Engineering, ASCE, 23(11).

![]() Ovuoba, B., and Prinz, G.S. (2018). “Investigation of residual fatigue life in shear studs of existing composite bridge girders following decades of traffic loading.” Engineering Structures, 161 (2018), pp.134-145.

Ovuoba, B., and Prinz, G.S. (2018). “Investigation of residual fatigue life in shear studs of existing composite bridge girders following decades of traffic loading.” Engineering Structures, 161 (2018), pp.134-145.

![]() Ovuoba, B., and Prinz, G.S. (2016). “On the fatigue capacity of headed shear studs in composite bridge girders” Journal of Bridge Engineering, ASCE, 21(12).

Ovuoba, B., and Prinz, G.S. (2016). “On the fatigue capacity of headed shear studs in composite bridge girders” Journal of Bridge Engineering, ASCE, 21(12).

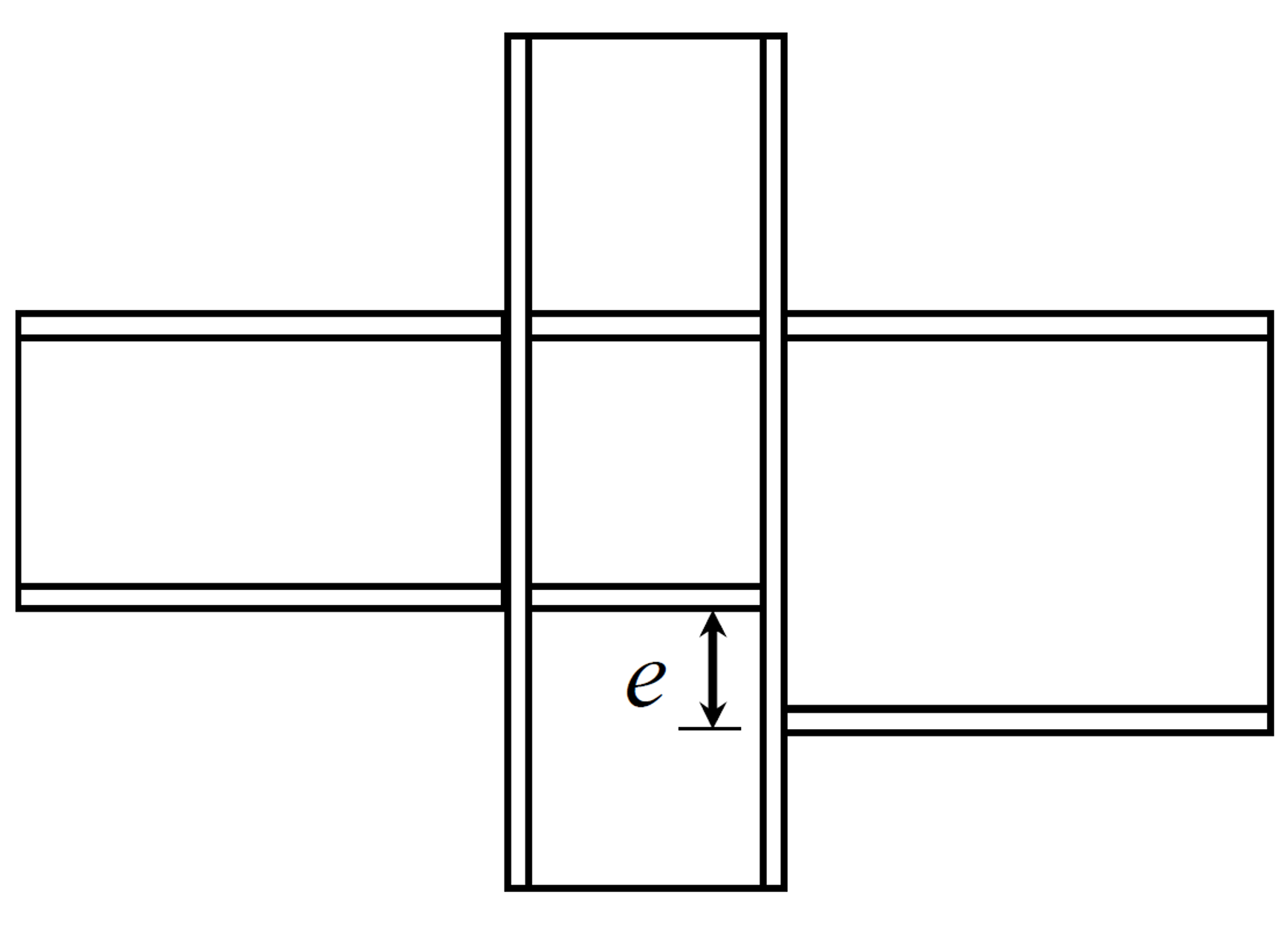

Beam-to-Column Continuity Plate Alignment Effects:

with Jason Norwood

In fully restrained beam-to-column moment connections, beam moments are mostly transferred to the connected column sections through tension-compression force couples that develop in the beam flanges. Column sections that are incapable of transferring these flange forces are often designed with continuity plates within the connection region to improve capacity. In cases of unequal beam depth framing into a column, an eccentricity between the framed-in beam flange and continuity plate may be required. Limited research exists to justify current guidance on acceptable levels of flange-to-continuity-plate eccentricity. Our research aims to quantify continuity plate eccentricity effects and provide guidance for beam-to-column connection detailing.

![]() Norwood, J., and Prinz, G.S. (2019). “Effect of Continuity-Plate Alignment on the Capacity of Welded Beam-to-Column Moment Connections.” Engineering Structures, [Under Review].

Norwood, J., and Prinz, G.S. (2019). “Effect of Continuity-Plate Alignment on the Capacity of Welded Beam-to-Column Moment Connections.” Engineering Structures, [Under Review].

Pre-Stressed CFRP Fatigue Retrofits for Improved Waterway Lock Reliability:

with Christine Lozano and Maggie Langston

Funded by the Maritime Transportation Research and Education Center (MarTREC)

Locks are essential to waterway transport for many river and canal systems, allowing passage of ships through areas of differing water elevation. Over 23M cargo tons passed US Army Corps locks in January of 2015 alone, and 19 locks aid water transport throughout Arkansas, Louisiana, and Mississippi. These waterway locks typically consist of large steel gates that are subject to large alternating forces as water levels are changed, and as lock gates open/close. Repeated loads, corrosive waterway environments, and component geometry can all contribute to fatigue/fracture issues that can limit lock gate service and inhibit the overall reliability of waterway transport. Unfortunately, fatigue issues within steel lock gate components are often only evident once the gates are emptied for routine service, or once serviceability is interrupted by structural failures. Lock service interruptions/repairs are costly (temporary repairs to the Montgomery Lock & Dam =$3.5M) but manageable from a fatigue perspective. Research into cheap, corrosion-tolerant fatigue retrofit solutions are needed. The following project addresses fatigue issues within lock gates, identifying critical components and exploring methods for preventing fatigue cracks for the entire gate component service life. The use of carbon fiber reinforced polymer (CFRP) plates will be explored along with innovative pre-stress and bonding strategies to fine-tune component stresses and improve fatigue life.

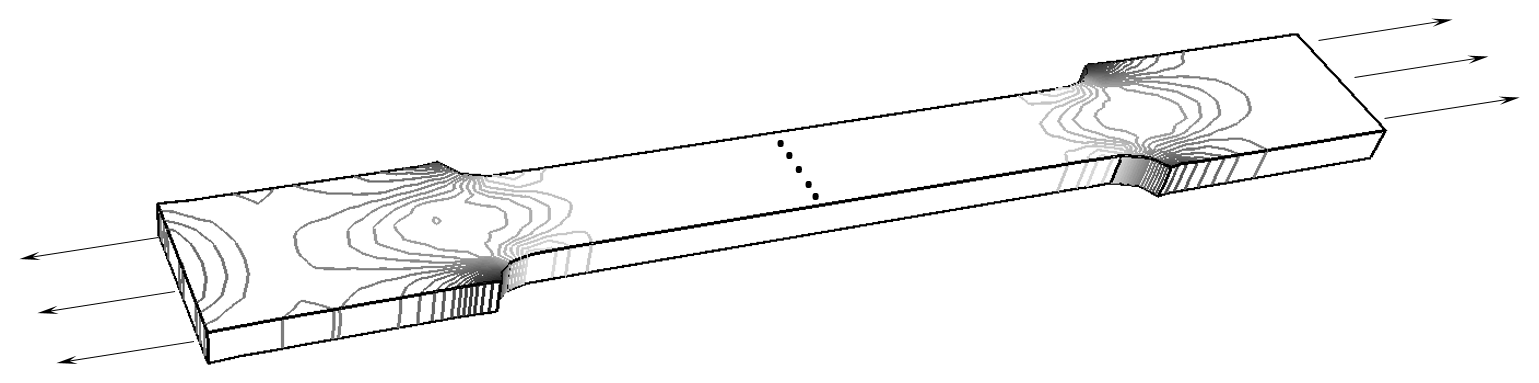

Automated pin-dot marking effects on A709-Gr50 Steel Plate Fatigue Capacity:

with Michael Noernberg

Supported by W&W|AFCO Steel

During fabrication of multi-piece steel assemblies, markings are often made on the steel surface to identify/track individual pieces or to provide reference for later erection. While these markings can be made by various manual methods (crayons, tags, die stamps, etc.) automated marking methods offer potential fabrication efficiencies by creating rapid computer controlled indentations in the steel surface through the repeated impact of hardened steel pins. For marked steel sections subjected to frequent or repeated loading (i.e. bridge girders, machinery components, etc.) surface indentations from these automated markings have the potential to alter component fatigue capacity. To account for marking effects, specifications often require additional experimental verification to ensure adequate fatigue performance. This research study experimentally investigates the effects of piece markings on bridge steel fatigue performance and compares capacities with existing AASHTO fatigue detail categories for compliance with AREMA specifications. Effects of the pin-dot marking frequency on fatigue susceptibility is also considered.

![]() Noernberg, M., and Prinz, G.S. (2018). “Automated Pin-Dot Marking Effects on Steel Bridge Component Fatigue Capacity.” Journal of Constructional Steel Research, 142(2018), pp.1-4.

Noernberg, M., and Prinz, G.S. (2018). “Automated Pin-Dot Marking Effects on Steel Bridge Component Fatigue Capacity.” Journal of Constructional Steel Research, 142(2018), pp.1-4.

Isolation of Carbide/Sulfide Inclusion Effects on Structural Steel

Ductile Fracture Processes:

with Qian Lin

Based on the underlying knowledge that metallic fractures initiate through a process of void growth around existing hard-phase particle (carbide/sulfide) inclusions, this exploratory research project focuses on an experimental approach to spatially characterize inclusion locations and measure steel alloy fracture characteristics at the micro- and macro-levels. This will leverage existing technology for a new purpose, and generate novel steel alloy fracture data at length scales not previously attempted. To better understand the fundamental processes driving ductile fracture within steel alloy materials, continuum properties and the local constitutive and damage response (which may contribute to fracture at larger scales) are measured from micro-steel specimens (diameters ranging from ~0.5 – 2microns in diameter) and macro-steel specimens (~3-4mm in diameter). These micro-specimens are fabricated through a series of focused ion beam (FIB) milling procedures, and are tested using modified nano-indentation devices capable of measuring applied forces and displacements at the micro level.

Evaluation and Repair of Existing Bridges in Extreme Environments:

with Korey Pough and Royce Floyd

Funded by the Southern Planes Transportation Center (SPTC)

Aging or deterioration of our nation’s bridge infrastructure is a significant problem that requires attention. In general this infrastructure deterioration can be attributed to two main factors, 1) corrosion, and 2) metallic fatigue, both of which work together to reduce structural capacity over time. Many of the bridges currently in service in Oklahoma, Arkansas, and throughout the southern plains region are reaching the end of their design lives or have been labeled structurally deficient either due to deterioration or differences between past and current code requirements. The goal of the proposed project is to produce comprehensive strategies for evaluation and resilient repair of prestressed concrete and steel bridge girders subjected to extreme environments in order to increase the longevity of existing structures. The effect of end region steel corrosion on capacity of prestressed concrete girders will be examined, with the objective of producing rating procedures related to corrosion level and repair designs incorporating residual strength. Innovative design strategies for corrosion resistant steel bridge fatigue retrofits will also be explored, to protect against environmental extremes and extend bridge fatigue life under increased levels of freight/truck traffic.

![]() Ghafoori, E., Motavalli, M., Nussbaumer, A., Herwig, A., Prinz, G.S., and Fontana, M. (2015). “Determination of minimum CFRP pre-stress levels for fatigue crack prevention in retrofitted metallic beams.” Engineering Structures, 84(2015), pp.29-41.

Ghafoori, E., Motavalli, M., Nussbaumer, A., Herwig, A., Prinz, G.S., and Fontana, M. (2015). “Determination of minimum CFRP pre-stress levels for fatigue crack prevention in retrofitted metallic beams.” Engineering Structures, 84(2015), pp.29-41.

![]() Ghafoori, E., Motavalli, M., Nussbaumer, A., Herwig, A., Prinz, G.S., and Fontana, M. (2015). “Design criterion for fatigue strengthening of riveted beams in a 120-year-old railway metallic bridge using pre-stressed CFRP plates.” Composites Part B, 68(2015).

Ghafoori, E., Motavalli, M., Nussbaumer, A., Herwig, A., Prinz, G.S., and Fontana, M. (2015). “Design criterion for fatigue strengthening of riveted beams in a 120-year-old railway metallic bridge using pre-stressed CFRP plates.” Composites Part B, 68(2015).

![]() Ghafoori, E., Prinz, G.S., Nussbaumer, A., Motavali, M., Herwig, A., and Fontana, M. (2014). “Finite element analysis for fatigue damage reduction in metallic riveted bridges using pre-stressed CFRP plates.” Polymers, 6(4), pp.1096-1118.

Ghafoori, E., Prinz, G.S., Nussbaumer, A., Motavali, M., Herwig, A., and Fontana, M. (2014). “Finite element analysis for fatigue damage reduction in metallic riveted bridges using pre-stressed CFRP plates.” Polymers, 6(4), pp.1096-1118.

![]() Ghafoori, E., Motavalli, M., Nussbaumer, A., Zhao, X.L., Herwig, A., Fontana, M., and Prinz, G.S. (2016). “A strengthening theory to prevent fatigue crack initiation in old metallic bridges.” 8th International Conference on Bridge Maintenance, Safety and Management (IABMAS) Foz do Iguaçu, Brazil.

Ghafoori, E., Motavalli, M., Nussbaumer, A., Zhao, X.L., Herwig, A., Fontana, M., and Prinz, G.S. (2016). “A strengthening theory to prevent fatigue crack initiation in old metallic bridges.” 8th International Conference on Bridge Maintenance, Safety and Management (IABMAS) Foz do Iguaçu, Brazil.

Steel Special Moment Frame Connections with Out-of-Plane Skew:

with Paul W. Richards and Clovis Desrochers

Steel special moment resisting frames (SMRFs) are a popular lateral force resisting system for steel buildings because of their architectural flexibility, providing brace-free spaces. Unusual building designs however, may require skewed moment connections. The most common SMRF connection (the reduced beam section, RBS) has never been tested with out-of-plane skew. Our research uses numerical methods to quantify SMRF skewed connection demands and help practicing engineers determine acceptable levels of skew wherein current RBS designs are still applicable.

![]() Desrochers, C., Prinz, G.S., and Richards, P.W. (2018). “Column axial load effects on the performance of skewed SMF RBS connections.” Journal of Constructional Steel Research, 150 (2018), pp. 505-513.

Desrochers, C., Prinz, G.S., and Richards, P.W. (2018). “Column axial load effects on the performance of skewed SMF RBS connections.” Journal of Constructional Steel Research, 150 (2018), pp. 505-513.

![]() Prinz, G.S. and Richards, P.W. (2016). “Demands on reduced beam section connections with out-of-plane skew.” J. Structural Engineering, ASCE, 142(1).

Prinz, G.S. and Richards, P.W. (2016). “Demands on reduced beam section connections with out-of-plane skew.” J. Structural Engineering, ASCE, 142(1).

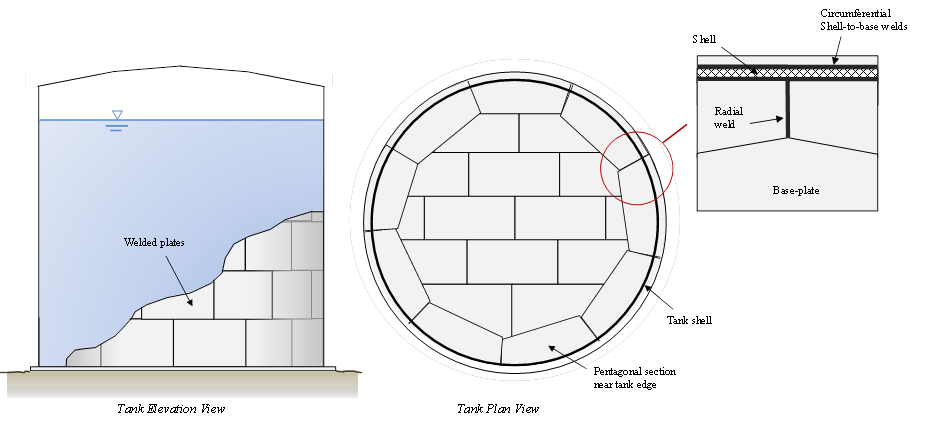

Effect of Radial Base-Plate Welds on the ULCF Performance of Tank Shell-to-Base Connections:

with Alain Nussbaumer

During severe earthquakes, the base connection region of large steel tanks is subjected to large inelastic rotations and possible ultra low-cycle fatigue (ULCF) damage. Because these large steel tanks are typically constructed by welding together much smaller steel plate sections, similar to construction of a patchwork quilt, there are two base connection scenarios to consider: 1) connections contained within an entire base-plate section, having only circumferential welds, and 2) connections at the junction of two base-plate sections, having both circumferential and radial welds. The Figure to the left shows a typical tank assembly, with the tank base having multiple pentagonal sections near the tank edge, forming a ring for connection of the tank shell. Connections having only circumferential welds have been tested in two recent studies by Dr. Prinz; however connections with both radial and circumferential welds have not been tested. Our research aims to experimentally quantify connection ULCF capacities for configurations having both transverse and radial welds and justify modifications to the current Eurocode standards.

During severe earthquakes, the base connection region of large steel tanks is subjected to large inelastic rotations and possible ultra low-cycle fatigue (ULCF) damage. Because these large steel tanks are typically constructed by welding together much smaller steel plate sections, similar to construction of a patchwork quilt, there are two base connection scenarios to consider: 1) connections contained within an entire base-plate section, having only circumferential welds, and 2) connections at the junction of two base-plate sections, having both circumferential and radial welds. The Figure to the left shows a typical tank assembly, with the tank base having multiple pentagonal sections near the tank edge, forming a ring for connection of the tank shell. Connections having only circumferential welds have been tested in two recent studies by Dr. Prinz; however connections with both radial and circumferential welds have not been tested. Our research aims to experimentally quantify connection ULCF capacities for configurations having both transverse and radial welds and justify modifications to the current Eurocode standards.

![]() Cortes, G., and Prinz, G.S. (2017). “Seismic fragility analysis of unanchored steel tanks considering local instability and fatigue damage.” Bulletin of Earthquake Engineering, 15(3), pp.1279-1295.

Cortes, G., and Prinz, G.S. (2017). “Seismic fragility analysis of unanchored steel tanks considering local instability and fatigue damage.” Bulletin of Earthquake Engineering, 15(3), pp.1279-1295.

![]() Prinz, G.S., and Nussbaumer, A.(2014). “Effect of radial base-plate welds on the ULCF capacity of tank connections.” J. Constructional Steel Research, 103(2014), p.131-139.

Prinz, G.S., and Nussbaumer, A.(2014). “Effect of radial base-plate welds on the ULCF capacity of tank connections.” J. Constructional Steel Research, 103(2014), p.131-139.

![]() Prinz, G.S., and Nussbaumer, A. (2012). “On the low-cycle fatigue capacity of unanchored steel liquid storage-tank shell-to-base connections.” Bulletin of Earthquake Engineering, 10(6), pp.1943-1958.

Prinz, G.S., and Nussbaumer, A. (2012). “On the low-cycle fatigue capacity of unanchored steel liquid storage-tank shell-to-base connections.” Bulletin of Earthquake Engineering, 10(6), pp.1943-1958.

![]() Prinz, G.S., and Nussbaumer, A. “Fatigue analysis of liquid storage-tank shell-to-base connections under multi-axial loading.” Engineering Structures, 40(2012), pp.75-82.

Prinz, G.S., and Nussbaumer, A. “Fatigue analysis of liquid storage-tank shell-to-base connections under multi-axial loading.” Engineering Structures, 40(2012), pp.75-82.

Effect of Concrete Slabs on the Seismic Performance of Eccentrically Braced Frame Systems:

with Albano de Castro e Sousa

Experimental testing of steel lateral force resisting systems or components often neglects interactions with the concrete slab. However, neglecting the concrete slab may have particular impact on predicting the performance of eccentrically braced frame (EBF) systems. In EBF systems, the in-plane slab stiffness could prevent relative column deformations, improving performance by somewhat inhibiting rotations within the link region. Additionally, the out-of-plane stiffness in the slab and slab-to-frame interactions may have restorative (self-centering) effects, reducing residual frame drifts. Our research aims to quantify slab contributions in EBFs with particular effort spent investigating the accumulation of ultra low-cycle fatigue damage within the link regions during dynamic loading.

Experimental testing of steel lateral force resisting systems or components often neglects interactions with the concrete slab. However, neglecting the concrete slab may have particular impact on predicting the performance of eccentrically braced frame (EBF) systems. In EBF systems, the in-plane slab stiffness could prevent relative column deformations, improving performance by somewhat inhibiting rotations within the link region. Additionally, the out-of-plane stiffness in the slab and slab-to-frame interactions may have restorative (self-centering) effects, reducing residual frame drifts. Our research aims to quantify slab contributions in EBFs with particular effort spent investigating the accumulation of ultra low-cycle fatigue damage within the link regions during dynamic loading.

![]() Prinz, G.S., and de Castro-e-Sousa, A. (2014). “Effect of slab stiffness on EBF link rotation demands and implications for link ultra low-cycle fatigue susceptibility.” ASCE Structures Congress, 2014, Boston, Massachusetts.

Prinz, G.S., and de Castro-e-Sousa, A. (2014). “Effect of slab stiffness on EBF link rotation demands and implications for link ultra low-cycle fatigue susceptibility.” ASCE Structures Congress, 2014, Boston, Massachusetts.

SSRL Intranet

SSRL Intranet